Consulting & Interim Management

|

Business consulting is helping organizations improve their performance, primarily through the analysis of existing business problems and development of plans for improvement.

In order to make decisions on how to improve a process, deliver better results, or make something more efficient, an organization must have access to data that can be measured. Only when a company has measurable data it can perform analysis on the data to determine trends, changes, or opportunities. SupplySquare’s expertise can help a department or organization determine major areas for improvement. SupplySquare’s expert can then work with company personnel to develop a solution or strategy for improvement, to take advantage of opportunities, or to create a corrective action plan. |

Fast roll-out of solutions that help SupplySquare can provide organizational change management assistance, development of specific skills, technology implementation, strategy development, or operational improvement services.

|

Interim Management is the rapid delivery of experienced ‘hands on’ executives for a defined period of time to deliver outcomes, implement change, fill unexpected gaps, restructure the organization, turn around under-performing projects or divisions or deliver a critical project.

Area's of Expertise

|

Production Planning, ERP & Operations Management Enterprise Resource Planning (ERP) systems integrate internal and external management information across an entire organization, embracing finance/accounting, production planning & control, operations & manufacturing, sales and service, customer relationship management, etc. ERP systems automate this activity with an integrated software application. The purpose of ERP is to facilitate the flow of information between all business functions inside the boundaries of the organization and manage the connections to outside stakeholders. SAP: MM – PP – SD – QM & Master Data GIB Planning & Operations

Are production bottlenecks, scheduling conflicts, and resource constraints holding your manufacturing operations back? Enhance your production processes with the GIB/IFM Production Planning and Scheduling solution, designed to seamlessly integrate with your SAP ERP system and revolutionize the way you manage your manufacturing operations. Why the GIB solution?

|

|

Business Process Automation - Aestiva Software

PaperlessOne is an Aestiva company and we’re consultants highly experienced in the area of business process management and automation. We assume you’re looking for a procurement solution, a timesheet tracking system, an expense or budget management system, or a system that involves one or more aspects of these kinds of systems. We assume you want to automate business processes that, without automation, you would do using paperwork or spreadsheets. If that is true, please read this web page. It may change the way you move forward. |

|

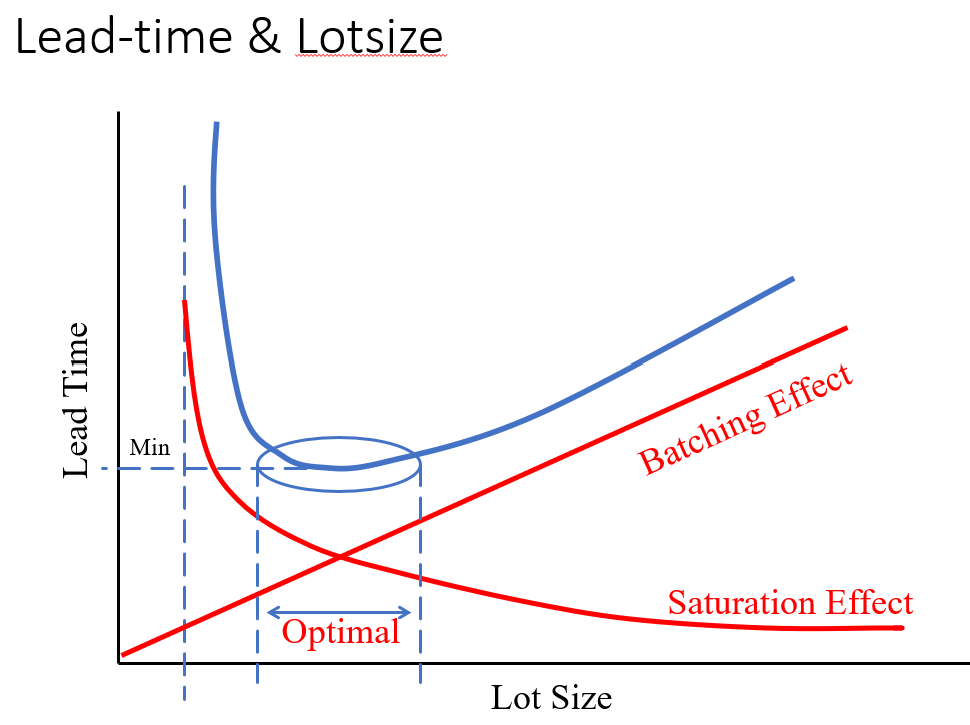

iCLIPS - Lead Time & Lot Size Optimization in Discrete Manufacturing

Many complex multi-item manufacturing shops have high levels of work-in-process because of queuing delays at machines and consequently long manufacturing lead times. We have the knowledge and the tools to help you optimize your ERP parameters. Aclips – A Capacity & Lead Time Integrated Procedure for Scheduling Load-Based POLCA: An Integrated Material Control System for Multiproduct, Multimachine Job Shops

| |||||||||||||